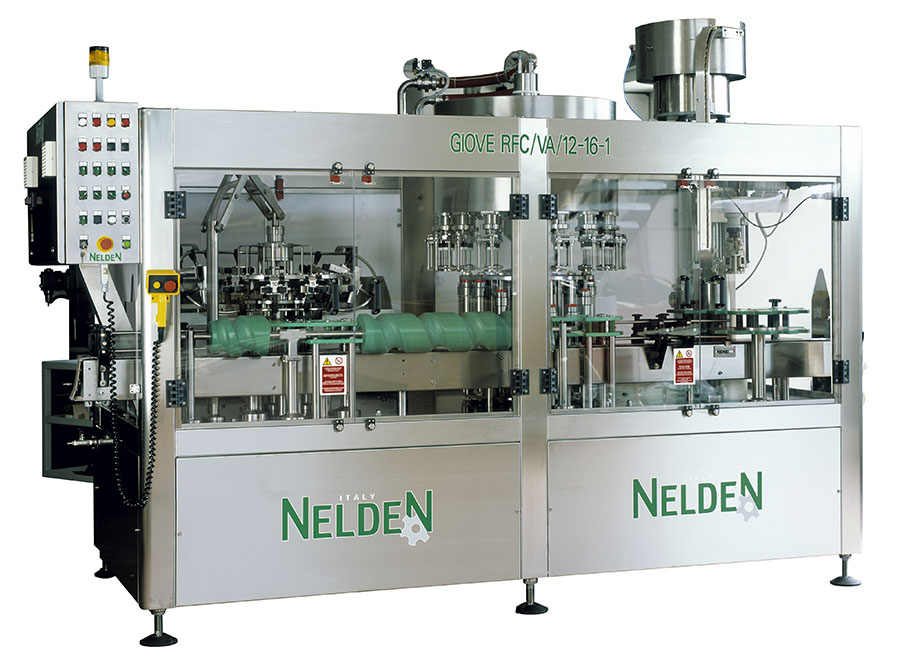

GIOVE

Level Gravimetric Mechanic Filling Machine for Glass and PET Bottles

Filling Monoblock GIOVE

Monoblocs GIOVE for Glass and PET Bottle congregate in a single machine the functions of rinsing, filling gravity / light pressure / slight vacuum / high vacuum for flat products, capping for all type of cap. It’s suitable to treat glass and PET bottles , cylindrical and shaped with outputs ranging from 1,500 up to 35,000 pcs / h.

The gravity valve of Nelden Industry, the machine’s true heart, has been studied to ensure a high productivity and precision of leveling the product inside the bottle. It has paid particular attention to the realization of the internal components of the valve in order to ensure an optimum level of sterility and maximum possibility of sanitization. For this reason, the mechanism is entirely made of AISI 304 and the sealing gaskets made of EPDM rubber.

In order to ensure maximum flexibility of our machines, such a valve is available in different models:

For bottling simple fall, es. still water;

Bottling light pressure, es. wine plate;

Bottling light vacuum, es. vodka;

For high vacuum bottling, es. liquids at high density;

For filling containers Mignon;

Each type of valve is also available in electronic version DE that, disengaging itself from the limits of mechanical movements, is able to manage the various phases of filling in the bottle by taking advantage of the rapidity of pneumatic systems and an electronic management of each individual phase.

Characteristics

Productivity from 1,500 to 35,000 pcs / h;

The machine is suitable for various types of still products and slightly sparkling, glass and PET bottles of any shape

Annular type Tank with conical bottom for total drainage

Possibility to work by gravity, under slight vacuum, or in an inert gas saturation (es. water, spirits, wine)

Ease of sanitization with false bottles and automatic integration system with CIP plant

Assurance of reliability over time thanks to the adoption of the best materiaIs

All of the Machine of GIOVE family are equipped with electrically adjustable height of the towers,

optional also available on the single head capping machines

Filling Valves

Mechanic Filling valve suitable to working gravity, a slight depression, and saturation with inert gas, according to the type of product to be treated

Completely made of stainless steel AISI 304 / 316L with external springs and the number of inner seals extremely reduced to guarantee maximum sterility and aseptic

The level adjustment is carried out by interposing spacers Weighted outside the tap; Available as an optional the centralized adjustment control

The geometry of the internal components is designed not to create shock to the product and to drain any trace of liquid during the steps of CIP

All configurations are equipped with an automatic system of anti-burst that immediately closes the valve in case of breakage of the bottle

All configurations can include the “centering mobile” system that avoids the collision between the bottle and the filling duct and stabilizes the bottle during the transfer at high speeds.

Look at our video on You Tube to see Our Bottling Plants in Function

In this video you can see a Complete Bottling Line with our monoblock Mod. “GIOVE RFC VA 50-50-10” For a production of 15,000 bottles per hour of Vodka in glass bottles